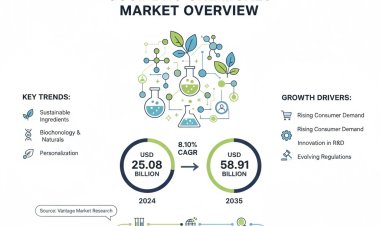

Global Carbon Fiber Market Size to Reach $14.2 Billion at a CAGR of 11.8% by 2030

Vantage Market Research expects the Carbon Fiber Market to reach USD 14.2 Billion by 2030, exhibiting a growth rate (CAGR) of 11.8% during 2023-2030.

The Global Carbon Fiber Market size reached USD 5.8 Billion in 2022. Vantage Market Research expects the market to reach USD 14.2 Billion by 2030, exhibiting a growth rate (CAGR) of 11.8% during 2023-2030.

Table of Contents

|

Introduction: |

|

|

The Future of Carbon Fiber: |

|

|

|

Innovations Shaping the Landscape: |

|

|

|

Industry Demand and Applications: |

|

|

|

|

Competitive Landscape: |

|

|

|

Conclusion: |

|

Introduction

The unique characteristics of Carbon Fiber, a material made of strong, thin crystalline filaments of carbon atoms, have transformed a number of industries. These qualities include high stiffness, low density, tensile strength, and chemical resistance. Its impact spans aerospace, automotive, sports, construction, and wind energy sectors, transforming how products are designed and manufactured.

Request Sample Report of Carbon Fiber Market @ https://www.vantagemarketresearch.com/carbon-fiber-market-2371/request-sample

Top Companies in Global Carbon Fiber Market

- A&P Technology Inc. (U.S.)

- Anshan Sinocarb Carbon Fibers Co. Ltd. (China)

- Hyosung Advanced Materials (South Korea)

- Jiangsu Hengshen Co. Ltd. (China)

- DowAksa USA LLC (U.S.)

- Formosa Plastics Corporation (U.S.)

- Hexcel Corporation (U.S.)

- Holding Company Composite (Russia)

- Mitsubishi Chemical Corporation (Japan)

- Nippon Graphite Fiber Co. Ltd. (Japan)

- SGL Carbon Solvay (Belgium)

- Teijin Limited (Japan)

The Future of Carbon Fiber

Today's Carbon Fibers are significantly more robust and lighter than steel, making them particularly appealing to industries where weight, strength, and efficiency are paramount. The aerospace and automotive sectors, in particular, are benefiting from the attributes of Carbon Fiber, leading to faster, stronger, and more fuel-efficient vehicles. One of the best examples is the Boeing 787 Dreamliner, which uses Carbon Fiber reinforcements to increase performance, decrease weight, and increase fuel efficiency. While the future seems bright for Carbon Fiber, cost remains a limiting factor. Manufacturing processes still need to be more expensive, hindering widespread adoption. However, industry professionals are optimistic, anticipating lower costs through advancements in manufacturing methods and more cost-effective input materials in the coming decades.

Development of Cost-Effective Carbon Fiber with Carbon Nanotubes

The integration of carbon nanotubes into Carbon Fiber opens up new possibilities. With a strength of 100 times that of steel and impressive electrical conductivity, carbon nanotubes could elevate the performance of Carbon Fiber even further. Overcoming the challenges of maintaining these superior properties in fibers, a research team successfully developed composite Carbon Fiber using carbon nanotubes and polyimide, achieving exceptional modulus and strength. This innovation holds promise for aerospace, military, and mobility applications.

Advanced Software Tools for Composite Product Development

The evolution of Carbon Fiber is not solely dependent on material advancements but also on the tools that facilitate its design and integration. Advanced software tools are crucial in automating engineering processes, reducing design cycle times, and identifying manufacturing feasibility upfront. These tools, ranging from design and analysis software to cost modelling tools, contribute to the efficient development of composite products, accelerating innovation in the Carbon Fiber industry.

Buy Now Our Carbon Fiber Industry Report @ https://www.vantagemarketresearch.com/buy-now/carbon-fiber-market-2371/0

Increasing Demand from Aerospace and Automotive Sectors

Carbon Fiber has revolutionized the aerospace industry by providing a combination of unmatched strength and lightness. It is a great option for aviation components because of its capacity to be molded into intricate structures and forms. The Boeing 787 Dreamliner serves as an excellent illustration of this, with its Carbon Fiber fuselage, wings, and tail. Carbon Fiber has significantly reduced weight compared to traditional materials like aluminium. An important consideration in the aviation sector is fuel efficiency, which is increased with this weight decrease. By utilizing Carbon Fiber, aircraft can achieve better fuel economy, longer flight ranges, and better performance. Furthermore, the maintenance benefits of Carbon Fiber's resistance to corrosion and fatigue are substantial. Unlike metal structures, Carbon Fiber components do not corrode, increasing durability and reducing maintenance costs. As a result, Carbon Fiber has become an essential part of modern aircraft design, with composite materials making up a significant portion of the overall structure.

In the automotive industry, Carbon Fiber is in high demand because of the industry's focus on energy efficiency and sustainability. Traditional vehicles made from steel and cast-iron face challenges with fuel consumption and carbon emissions. To address these issues, researchers and manufacturers are looking into using lightweight materials like Carbon Fiber to improve vehicle performance. The necessity for strong, lightweight materials in the industry has been addressed by Carbon Fiber composites. Even a small reduction in vehicle weight, such as 10 kilograms, can lead to lower fuel consumption and carbon emissions. Carbon Fiber is becoming more essential to create greener and more sustainable transportation as concerns about the environment and fuel efficiency grow. Luxury car makers incorporate Carbon Fiber components into their vehicles to balance performance, safety, and environmental consciousness. Carbon Fiber is used in various car parts, from the body panels to the interior components. This improves fuel efficiency and enhances the overall driving experience, making Carbon Fiber a symbol of innovation and luxury in the automotive industry.

Regional Landscape

The Asian market, particularly China and India, is emerging as a significant player in the Carbon Fiber industry. China's plans to purchase thousands of new aircraft in the next two decades indicate a substantial market demand for Carbon Fiber. In India, efforts to reduce CO2 emissions align with the global push for sustainable practices, potentially driving the adoption of Carbon Fiber in various industries.

Competitive Landscape

Several key players in the Carbon Fiber industry are making strategic moves to expand their market presence. Collaborations, acquisitions, and advancements in manufacturing technologies are shaping the competitive landscape.

- Argosy International Inc. and Formosa Plastics Partnership: In August 2023, Argosy International Inc. partnered with Formosa Plastics to expand Formosa's Advanced Materials Composites business in North America. This collaboration combines Formosa's plastics and Carbon Fiber expertise with Argosy's high-technology specialty materials experience.

- Hexcel's Showcase of Innovative Technologies: In October 2023, Hexcel unveiled new lightweight material technologies, including intermediate and high modulus fiber HexPly® M79 prepregs. These innovations cater to highly loaded components in structures like rigs and foils, demonstrating Hexcel's commitment to providing cutting-edge solutions for industries such as America's Cup and IMOCA.

- Formosa Plastics Group and CATACK-H Cooperation: In January 2023, Formosa Plastics Group partnered with South Korean start-up CATACK-H to offer comprehensive solutions, including virgin and recycled Carbon Fibers. CATACK-H's patented technology enables the processing of Carbon Fiber waste into high-quality recycled products, aligning with the industry's focus on sustainability.

- Hyosung Advanced Materials Expansion: In September 2023, Hyosung Advanced Materials announced the establishment of a new subsidiary in Vietnam to expand its Carbon Fiber production. This investment reflects Hyosung's commitment to meet the increasing global demand for Carbon Fiber in applications such as Urban Air Mobility, CNG, hydrogen high-pressure vessels, and wind turbine blades.

- Mitsubishi Chemical Group's Acquisition of CPC SRL: In October 2023, Mitsubishi Chemical Group acquired CPC SRL, an Italian company specializing in manufacturing automobile components from Carbon Fiber-reinforced plastic. This acquisition enhances Mitsubishi Chemical Group's vertically integrated Carbon Fiber supply chain and enables using Carbon Fiber composite materials in automotive components.

Conclusion

The Carbon Fiber market is witnessing dynamic changes driven by technological advancements, increasing demand from key industries, and strategic collaborations. While challenges like manufacturing costs persist, ongoing research and innovations, such as integrating carbon nanotubes, promise to overcome these hurdles. As the global focus on sustainability intensifies, Carbon Fiber's role in revolutionizing industries and contributing to an eco-friendly future becomes increasingly evident. The evolving landscape of the Carbon Fiber market presents exciting opportunities for growth, innovation, and a sustainable future.

Read Our Latest Press Release: Dental Equipment Market - In-depth Analysis

Contact us

Eric Kunz

6218 Georgia Avenue NW Ste 1 - 564

Washington DC 20011-5125

United States Tel: +1 202 380 9727

Email: [email protected]

Website: Vantage Market Research