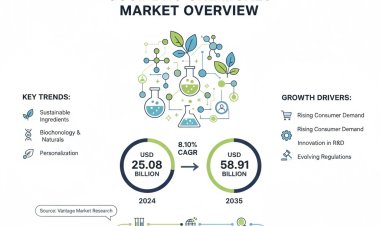

Global Powder Coatings Market Size to Reach $22.4 Billion at a CAGR of 5.9% by 2030

Vantage Market Research expects the Powder Coatings Market to reach USD 22.4 Billion by 2030, exhibiting a growth rate (CAGR) of 5.9% during 2023-2030.

The Global Powder Coatings Market size reached USD 14.2 Billion in 2022. Vantage Market Research expects the market to reach USD 22.4 Billion by 2030, exhibiting a growth rate (CAGR) of 5.9% during 2023-2030.

Table of Contents

|

Introduction |

|

|

|

Understanding Powder Coating |

|

|

|

|

Application Techniques |

|

|

|

|

Types of Powder Coating |

|

|

|

Driving Forces for Growth |

|

|

|

|

Powder Coatings and Sustainability |

|

|

|

|

|

|

|

Competitive Landscape |

|

|

|

|

|

Conclusion |

|

|

|

|

Introduction

Powder coating, a revolutionary surface finishing technique, has transformed industries’ approach to coating applications. Since its introduction in Australia around 1967, powder coating has gained widespread popularity due to its efficiency, durability, and environmental sustainability.

Request Sample Report of Powder Coatings Market @ https://www.vantagemarketresearch.com/powder-coatings-market-2378/request-sample

Top Companies in Global Powder Coatings Market

- AkzoNobel N.V. (Netherlands)

- PPG Industries (U.S.)

- Axalta Coating Systems (U.S.)

- Kansai Nerolac Paints Limited (India)

- Sherwin Williams (U.S.)

- BASF SE (Germany)

- Jotun IFS Coatings (U.S.)

- The Valspar Corporation (U.S.)

Understanding Powder Coating

Powder coating is a method of applying dry paint to a component. The resulting coating is equivalent to a wet paint that is applied in two separate layers. In traditional wet painting, the solids are mixed in a liquid substance and need to evaporate before forming the solid paint coating. However, powder coating is a dry process where resin and pigment particles are finely ground and charged with electricity before being sprayed onto electrically grounded parts. Similar to liquid coatings, the parts to be coated undergo a pre-treatment process before being coated and cured. This pre-treatment usually takes place consecutively with the coating and curing processes.

Application Techniques

Two standard methods dominate powder coating applications: electrostatic spray and fluidized bed powder coating. The fluidized bed, the original technique, is preferred for thermoplastic powder application. Conversely, electrostatic spray is the primary method for thermosetting powder, where charged particles adhere to grounded parts, forming a continuous film upon melting and merging in a curing oven.

Types of Powder Coating

Powder Coatings are categorized into thermoplastic and thermosetting varieties.

Thermoplastic Powder Coating: Thermoplastics melt and flow when exposed to heat but maintain their chemical composition upon cooling. Commonly applied using the fluidized bed technique, thermoplastic powders, such as nylon, exhibit excellent chemical resistance, toughness, and flexibility.

Thermosetting Powder Coating: Thermosetting Powder Coatings, based on lower molecular weight solid resins, crosslink chemically upon melting. Epoxy, polyester, and acrylic resins are the foundation for various coating systems, with recent technological advancements primarily focused on thermosetting powders.

Driving Forces

Several factors contribute to the expanding Powder Coatings market.

The rise in manufacturing facilities and industrialization in developing countries fuels the demand for Powder Coatings, particularly in floor applications. The non-porous, easy-to-clean, and affordable nature of these coatings, coupled with regulatory emphasis on safety, contributes to market growth. Technological innovations, such as low-temperature cures and powders meeting high durability standards, enhance the market's competitiveness. The shift from solvent-borne paints to Powder Coatings, driven by environmental regulations, further propels the industry.

Buy Now Our Powder Coatings Industry Report @ https://www.vantagemarketresearch.com/buy-now/powder-coatings-market-2378/0

Powder Coatings and Sustainability

One of the most compelling aspects of Powder Coatings lies in their inherent sustainability, making them a preferred choice for environmentally conscious industries and consumers. Several factors contribute to the sustainable nature of Powder Coatings, addressing environmental concerns and aligning with global initiatives for greener practices.

Powder Coatings are renowned for their low carbon footprint and minimal environmental impact throughout their lifecycle. Unlike traditional liquid coatings that often contain VOCs (volatile organic compounds) and HAPs (hazardous air pollutants), Powder Coatings are solvent-free. The absence of solvents eliminates the release of harmful substances into the atmosphere during application, contributing to improved air quality.

The application process of Powder Coatings minimizes waste generation, emphasizing their eco-friendly characteristics. When applying, extra powder that doesn't stick to the substrate can be gathered and utilized again. This reduces the need for expensive hazardous waste disposal systems and supports a more sustainable, cost-effective coating solution. The efficiency of Powder Coatings in terms of material utilization contributes to resource conservation.

Powder Coatings typically require only one coat to achieve the desired protective and decorative finish. This efficiency contrasts with some liquid paint systems that may necessitate multiple coats for comparable results. The durability of Powder Coatings is a key sustainability factor. These coatings exhibit exceptional resistance to extreme weather conditions, UV exposure, moisture, and erosion. The longevity of the coating reduces the frequency of reapplication, extending the lifespan of coated products and minimizing resource consumption.

Powder Coatings align with stringent environmental standards and codes, including those set by organizations like the U.S. Green Building Council LEED v4. The United States EPA (Environmental Protection Agency) recognizes Powder Coatings as a sustainable coating option. This recognition extends to their ability to satisfy various industry-specific standards, such as the American Architectural Manufacturers Association (AAMA) 2605 and Qualicoat Class 3, which demand high durability over an extended period.

The application process for Powder Coatings often involves lower energy consumption than traditional coating methods. Additionally, advancements in low-temperature cure technologies contribute to energy efficiency, reducing the overall environmental impact. Powder Coatings emit negligible VOCs during application and cure, promoting a healthier working environment and minimizing contributions to air pollution.

Recent developments in powder coating materials focus on sustainability through renewable monomers and recycled materials. Innovations in polyester resins, the key components of Powder Coatings, have resulted in formulations that reduce reliance on traditional oil-based monomers. Some patented platforms offer resins entirely based on renewable sources, contributing to the industry's shift toward environmentally friendly and sustainable technologies.

Competitive Landscape

Key players in the Powder Coatings market continue to innovate and expand their offerings.

- AkzoNobel's Energy Savings Calculator: In June 2023, AkzoNobel introduced the industry's first online energy savings calculator for Powder Coatings. The company's aim to cut carbon emissions by 50% by 2030 is in line with this strategy, which emphasizes how crucial sustainability is becoming to the business world.

- Sherwin-Williams' Support Services: In September 2023, Sherwin-Williams General Industrial Coatings Division introduced services like FASTtrack, Stocked Powder Program, and E-Commerce Store, providing fast and reliable support to businesses of all sizes involved in powder coating applications.

- PPG's Plant Expansion: PPG's expansion of its Powder Coatings plant in Sumaré, Brazil, demonstrates the industry's response to growing demand. With a $2.7 million investment, the project increases production capacity by 40%, incorporating state-of-the-art equipment for improved process control and quality.

- BASF and Zhejiang Guanghua Technology Co., Ltd.: BASF's collaboration with Zhejiang Guanghua Technology Co., Ltd. for the supply of Neopentyl Glycol (NPG) signifies the importance of strategic partnerships in the Powder Coatings industry. The plan to build a high-end Powder Coatings resins production plant in the Zhanjiang Economic & Technological Development Zone reflects the continuous growth and expansion of the market.

Conclusion

The Powder Coatings market is undergoing a significant transformation driven by technological advancements, sustainability considerations, and the pursuit of higher efficiency. As industries worldwide prioritize environmentally friendly and durable coating solutions, Powder Coatings emerge as a key player. With continuous innovation, strategic partnerships, and a commitment to sustainability, the Powder Coatings market is poised for sustained growth in the coming years.

Read Our Latest Press Release: Precious Metals Market - In-depth Analysis

Contact us

Eric Kunz

6218 Georgia Avenue NW Ste 1 - 564

Washington DC 20011-5125

United States Tel: +1 202 380 9727

Email: [email protected]

Website: Vantage Market Research