Top 5 Industries Revolutionized by Thermoplastic Polyimide Elastomers in 2025

Discover how thermoplastic polyimide elastomers are revolutionizing industries like aerospace, automotive, electronics, healthcare, and energy in 2025 with unmatched performance and sustainability.

In 2025, thermoplastic polyimide elastomers (TPIEs) have emerged as a game-changing material across multiple industries. With their exceptional thermal stability, chemical resistance, mechanical strength, and flexibility, TPIEs are now the preferred choice for next-generation product development. From enabling the latest in aerospace engineering to improving energy efficiency in renewable technologies, thermoplastic polyimide elastomers are revolutionizing the way products are designed, manufactured, and used.

This blog explores the top 5 industries transformed by thermoplastic polyimide elastomers in 2025, with a close look at key innovations, market trends, and future outlooks. If you’re a materials scientist, product engineer, or business strategist, this deep dive will help you understand why TPIEs are the future.

What Are Thermoplastic Polyimide Elastomers?

Thermoplastic polyimide elastomers are a class of high-performance polymers known for combining the flexibility of elastomers with the strength and heat resistance of polyimides. These materials offer:

- Excellent thermal stability (up to 300°C)

- High mechanical strength and toughness

- Outstanding chemical and oxidative resistance

- Superior dimensional stability

- Ease of processing and recyclability

Thanks to these properties, TPIEs outperform conventional elastomers in extreme conditions and are widely used in applications that demand durability, lightweight design, and high temperature tolerance.

Why Are Thermoplastic Polyimide Elastomers Important in 2025?

In 2025, industries are driven by sustainability, miniaturization, and smart manufacturing. TPIEs align perfectly with these goals by offering:

- Longer product life cycles

- Lower environmental impact due to recyclability

- Improved product performance

- Reduced maintenance costs

As companies move toward greener and smarter solutions, the demand for materials like thermoplastic polyimide elastomers is accelerating.

Top 5 Industries Revolutionized by Thermoplastic Polyimide Elastomers in 2025

Aerospace and Defense

The aerospace and defense sector is perhaps the most prominent beneficiary of thermoplastic polyimide elastomers in 2025.

Key Applications:

- Lightweight structural components

- Thermal insulation in jet engines

- Flexible seals and gaskets in space applications

- Cable sheathing for extreme environments

TPIEs are instrumental in designing next-gen aircraft and space exploration vehicles. With their high heat resistance and lightweight properties, these elastomers contribute to fuel efficiency and performance.

Market Insights:

- The aerospace composites market has grown by 14% YoY in 2025, with TPIEs contributing to a significant portion of that growth.

- Major defense contractors are integrating TPIEs into their next-gen hypersonic weapon systems and UAVs (unmanned aerial vehicles).

Automotive Industry

In 2025, the automotive industry is undergoing a massive transformation, especially in the electric vehicle (EV) and autonomous driving segments.

How TPIEs Are Transforming the Sector:

- Lightweight under-the-hood components that withstand extreme temperatures

- Battery housing and insulation for electric vehicles

- Noise and vibration dampening seals for a smoother ride

- Heat-resistant wiring harnesses

The high demand for electric mobility has increased the need for durable and heat-resistant materials. TPIEs are helping automotive OEMs reduce vehicle weight while maintaining high performance standards.

Electronics and Semiconductors:

The electronics and semiconductor industry thrives on miniaturization, heat dissipation, and component reliability. Thermoplastic polyimide elastomers have become essential in 2025 for manufacturing robust electronic components.

Common Use Cases:

- Flexible printed circuit boards (PCBs)

- Thermal interface materials

- Wire coatings and connectors

- Dielectric layers in high-frequency devices

As 5G, AI, and IoT demand faster, smaller, and more efficient hardware, TPIEs provide the necessary reliability and thermal management. Startups focusing on wearable tech are increasingly adopting TPIEs for their flexible yet durable electronics.

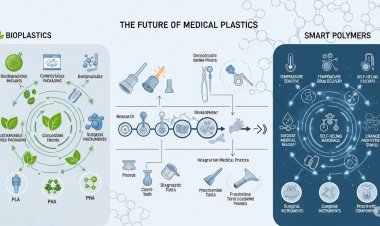

Medical Devices and Healthcare

In the healthcare sector, biocompatibility, sterilization resistance, and mechanical performance are non-negotiable. Thermoplastic polyimide elastomers offer these advantages, making them vital for modern medical device engineering.

TPIEs in Healthcare Applications:

- Catheters and tubing for minimally invasive procedures

- Implantable components due to excellent chemical resistance

- Wearable health monitors needing flexibility and skin safety

- Surgical tool insulation

With the rise in personalized medicine and point-of-care devices, TPIEs enable safer and more effective products that improve patient outcomes.

Energy and Power Generation

The energy sector, particularly renewables and advanced grid technologies, is leveraging TPIEs to enhance efficiency and safety in harsh environments.

Energy-Specific Applications:

- High-voltage cable insulation

- Sealants in wind turbines

- Oil and gas exploration tools

- Encapsulation materials for photovoltaic systems

As power systems evolve to become smarter and more decentralized, TPIEs support higher operational temperatures and improve lifecycle costs.

Renewable Energy Boost:

- Wind and solar farms in extreme climates are now deploying TPIE-based sealing systems for durability.

- In nuclear applications, thermoplastic polyimide elastomers help manage radiation and thermal stress.

Market Key Drivers:

- Increasing demand for miniaturization in electronics

- Growth of EV and autonomous vehicle markets

- Emphasis on sustainable and recyclable polymers

- Expansion in space missions and defense budgets

Key Players in the Market:

- Solvay S.A.

- Mitsui Chemicals

- SABIC

- DuPont

- Ensinger

These companies are investing heavily in R&D to create custom formulations of TPIEs for niche applications.

Final Thoughts:

Thermoplastic polyimide elastomers are not just another high-performance material—they are at the core of the innovation ecosystem in 2025. From improving EV performance to enabling space travel, TPIEs are truly revolutionizing multiple industries.

By integrating these advanced elastomers into their products, manufacturers are gaining a competitive edge, reducing lifecycle costs, and supporting sustainability goals.

As market demands continue to evolve, one thing is certain: thermoplastic polyimide elastomers will play a pivotal role in shaping the future of high-performance materials.