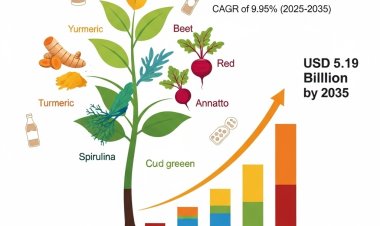

Global Protective Packaging Market Size, Growth, Trends, and Forecast 2025-2035

The global protective packaging market is set to grow from USD 30.34 Billion in 2024 to USD 49.6 Billion by 2035, at a CAGR of 4.58%. Discover key market drivers, trends, and forecasts for the next decade.

The global Protective Packaging Market is essential for safeguarding products from damage during transit, storage, and handling. As industries such as e-commerce, food & beverage, healthcare, and industrial goods expand rapidly, demand for reliable protective solutions—rigid, flexible, foam, cushioning, blocking & bracing, void fills, insulation, wrapping—has surged. Based on the latest data from Vantage Market Research, this press release presents the 2024 revenue, forecasts through 2035, segmentation insights, regional trends, key company activity, recent developments, and market dynamics shaping this crucial sector.

Our comprehensive Protective Packaging Market report is ready with the latest trends, growth opportunities, and strategic analysis. View Sample Report PDF.

Key Takeaways

- 2024 Revenue: The Protective Packaging Market is valued at USD 30.34 Billion for 2024.

- Forecast 2035: Expected to reach USD 49.60 Billion by 2035.

- CAGR (2025-2035): Projected growth at 4.58% annually.

- Largest and Fastest-Growing Region: Asia Pacific leads in both revenue and growth.

- Dominant Segments: By type, flexible protective packaging holds the largest share; by material, foam plastics dominate; by function, cushioning and void fill are key; by application, food & beverage, industrial goods, healthcare, automotive, household appliances and others are major end-uses.

Premium Insights

The market is largely driven by the rise of e-commerce and global trade, resulting in high demand for packaging that can minimize damage during shipping. Sustainability is increasingly important—companies are investing in recyclable, biodegradable, and compostable materials. Foam plastics remain popular because of their strong shock absorption and insulation properties, but alternatives like paper & paperboard are gaining traction due to environmental concerns. Functionally, cushioning, void fill, and wrapping dominate due to their role in product protection. Manufacturers are innovating in flexible packaging types, balancing cost, protection, and environmental performance. Regulations (especially in food safety, pharmaceuticals and environmental protection) are reinforcing demand for higher performance and safer protective packaging.

Market Size & Forecast

- 2024: USD 30.34 Billion global market value.

- 2035: Forecast to reach USD 49.60 Billion by 2035.

- CAGR (2025-2035): Expected at 4.58% growth per annum.

The protective packaging market shows a mix of large global players alongside regional and local manufacturers. Large firms tend to lead in R&D, material technology (foam plastics, biodegradable materials), and broad distribution. Smaller players often focus on niche materials, specialty functions (e.g. for fragile goods, medical applications), or regional sustainability compliance. The market is moderately competitive; barriers include raw material cost fluctuations (foam, plastics, paper), environmental regulation, shipping/logistics costs, and customer expectations for both protection and sustainability. Because protection functions can vary based on product fragility, transportation environment, temperature, moisture, vibration etc., customization and local standards are also key characteristics.

For Protective Packaging Market Research Report and updates detailed: View Full Report Now!

Type Insights

The protective packaging market by type includes rigid, flexible, and foam packaging. Rigid packaging dominates due to its strong protective capabilities in transporting fragile and high-value goods, particularly in electronics and industrial applications. Flexible packaging is widely adopted for its lightweight nature and cost efficiency, making it popular in e-commerce and food packaging. Foam packaging is critical for cushioning sensitive items such as healthcare devices and appliances. Growing demand for sustainable solutions is driving innovation across all protective packaging types.

Material Insights

Based on material, the market is segmented into paper & paperboard, plastics, and others. Paper & paperboard is gaining significant traction as eco-friendly packaging solutions align with global sustainability initiatives. Plastics continue to hold a major share due to their durability, versatility, and barrier properties, though regulatory pressure is encouraging recycling-focused innovations. Other materials, including biodegradable and advanced composites, are emerging as alternatives to reduce environmental impact. The material mix is evolving as industries balance cost, strength, and environmental responsibility.

Function Insights

The protective packaging market by function is divided into cushioning, void-fill, insulation, wrapping, and others. Cushioning solutions lead the market due to their vital role in protecting fragile items during shipping, especially in e-commerce and electronics. Void-fill packaging, often lightweight and cost-efficient, is growing with the surge in parcel deliveries. Insulation is increasingly essential for temperature-sensitive products such as food and pharmaceuticals. Wrapping materials provide surface protection against scratches and contamination. Together, these functions address diverse industry needs while emphasizing product safety and sustainability.

Application Insights

Applications of protective packaging span food & beverages, industrial goods, healthcare, automotive, consumer goods, and others. The food & beverage sector dominates, driven by rising global demand for safe, hygienic, and sustainable packaging. Industrial goods and automotive sectors rely heavily on protective solutions for transporting bulky, delicate, and high-value components. Healthcare packaging is growing rapidly, fueled by pharmaceutical shipments and medical device safety requirements. Consumer goods packaging, boosted by e-commerce growth, demands innovative lightweight solutions. Each application highlights the crucial role of protective packaging in global supply chains.

Regional Insights

North America Protective Packaging Market Trends

North America represents a mature market with robust regulation around product safety, environmental standards, and packaging waste. Demand here is driven by e-commerce logistics, industrial goods, electronics, and healthcare sectors. Consumers and brands increasingly demand recyclable, compostable, or bio-based packaging. Cost pressures from transportation and raw materials are significant. Innovation in packaging (like compostable trays, overwraps if replacing EPS, plant-based barrier materials) is more common here. Local manufacturers compete on sustainability credentials and ability to supply regionally. Recent capacity expansions (factories, R&D) happen especially in U.S. and Canada.

Europe Protective Packaging Market Trends

Europe’s market is strongly shaped by regulatory frameworks around waste, recycling, packaging waste directives, extended producer responsibility (EPR), and consumer environmental awareness. Paper & paperboard materials see higher adoption here, as do stricter rules for plastic use. Companies often aim for certifications, use of PCR (post-consumer recycled content), and innovations in compostable or biodegradable materials. Industries such as food & beverage, pharmaceuticals, automotive have demanding standards, and packaging must often meet them. Demand for efficient, minimal packaging that nevertheless protects goods, along with strong supply chain and logistics infrastructure, supports premium protective packaging solutions.

Asia Pacific Protective Packaging Market Trends

Asia Pacific is the largest and fastest-growing region in protective packaging. High growth in e-commerce, industrial production, electronics, consumer durables, and pharmaceuticals drives demand. Rising income, urbanization, and retail expansion add to demand for protective packaging. Raw materials and production capacity are expanding locally. However, environmental pressures are increasing—governments are introducing regulations on plastic waste, encouraging paper-based or bio-based protective materials. Cost sensitivity remains high, pushing innovation in cost-efficient protective packaging. Markets such as India, China, Southeast Asia are central to growth.

Latin America Protective Packaging Market Trends

In Latin America, the protective packaging market is growing steadily but somewhat behind Asia Pacific and mature Western markets. Growth comes from rising e-commerce, import/export goods, retail sector expansion. Key constraints include infrastructure, cost of imported materials, lower per-capita spending, and weaker regulatory enforcement in some countries. There’s also increasing interest in sustainability, but transitions (from foam/plastic to paper or compostable materials) may lag. Domestic manufacturers often compete with imports. Customization and cost-effective flexible packaging are important here.

Middle East & Africa Protective Packaging Market Trends

Middle East & Africa is smaller in volume, but important opportunities are emerging with growth in trade, industrialization, oil & gas, healthcare, and e-commerce. Some countries invest heavily in logistics and infrastructure, which supports demand for protective packaging. Environmental regulation is less strict on average, but awareness is rising. Resource constraints (raw materials, production capacity, energy costs) and high transportation costs can be limiting. Custom protection for harsh climates (heat, humidity) is often needed. Flexible and foam packaging are popular for light weight and cost reasons, but sustainability concerns are becoming more relevant.

Top Key Protective Packaging Companies

Some of the leading global companies in the protective packaging market include:

- Sealed Air Corporation

- Sonoco Products Company

- Smurfit Kappa Group

- DS Smith plc

- Huhtamaki

- Pregis LLC

- Protective Packaging Inc.

- Storopack Hans Reichenecker GmbH

- The Dow Chemical Company

- Amcor

These companies compete on material innovation (foam, bio-based plastics, sustainable alternatives), functionality (better cushioning, insulation, wrapping), cost efficiency, distribution reach, and regulatory compliance. Many are investing in new product development, expansion of production capacity, sustainability initiatives (PCR, compostable, recyclable materials), and supply-chain resilience.

Recent Developments

- In September 2024, Storopack launched RENATURE® 3D protective packaging, made primarily from plant starch (yellow pea by-product), which is reusable, home compostable, and designed to replace EPS. It provides equivalent protection, can be formed into custom shapes, and is certified “OK COMPOST HOME” by TÜV Austria.

- In January 2024, SEE (Sealed Air) introduced a compostable overwrap tray made from biobased, food-contact rated resin (≈ 54% biobased content), as a biodegradable alternative to EPS trays, maintaining equivalent performance.

Protective Packaging Industry Scope

The report provides quantitative and qualitative insights, profiling market drivers, restraints, opportunities, and challenges. It segments the market by Type (Rigid, Flexible, Foam), by Material (Foam Plastics; Paper & Paperboard; Plastics; Others), by Function (Cushioning; Blocking & Bracing; Void Fill; Insulation; Wrapping), by Application (Food & Beverage; Industrial Goods; Healthcare; Automotive; Household Appliances; Others), and by Region (North America; Europe; Asia Pacific; Latin America; Middle East & Africa). Additionally, the report profiles major companies, examines recent product and sustainability innovations, supply chain trends, regulatory impacts, and evolving consumer preferences toward sustainable and efficient packaging.

Market Dynamics

Driver

Growing global e-commerce, logistics, and trade volumes are primary drivers. As more goods are shipped over long distances, the risk of damage, shrinkage, spoilage increases. Protective packaging solutions reduce losses, protect product integrity, and improve customer satisfaction. Additionally, consumer awareness and regulatory pressure around sustainability are pushing companies to adopt recyclable, compostable, or reusable materials—boosting innovation and demand for greener protective packaging. Rising disposable incomes in emerging markets further add to demand for durable and reliable packaging.

Restraint

Key restraints include the cost and availability of raw materials—foam plastics, certain plastics, and high-performance protective components can be expensive and subject to supply volatility. Environmental regulations and bans on certain plastics add compliance and redesign cost burdens. Production costs, energy costs, and transportation/logistics costs also constrain margins. Price sensitivity in many markets—especially for low-value goods—makes premium protective packaging investments difficult. Another restraint is that sustainable alternatives often underperform traditional foams/plastics in protection or durability, requiring trade-offs.

Opportunity

Significant opportunities lie in developing bio-based, compostable, and recyclable materials to meet regulatory and consumer demands. Custom protective packaging that adapts to product shape and fragility can reduce material use and improve efficiency. Innovations in flexible packaging types and advanced manufacturing (e.g., foam in place, molded pulp, plant-based alternatives) are likely growth areas. Emerging economies in Asia Pacific, Latin America, and Middle East & Africa offer expanding markets. Also, combining protection with functionalities—such as insulation, smart sensors, or active protection—opens new application domains.

Challenges

Challenges faced by the market include balancing protection performance with sustainability—making packaging both protective and environmentally benign. Ensuring consistent quality across regions and maintaining supply chains in the face of material shortages, regulatory shifts, and energy cost inflation is difficult. Also, educating customers and end-users about new materials (e.g. compostable, bio-based) so they understand performance and disposal behavior. Competition from low-cost producers, shifting trade policies, and logistical complexities (particularly in remote or developing regions) also present barriers.

Global Protective Packaging Market Segmentation

- By Type: Rigid Protective Packaging; Flexible Protective Packaging; Foam Protective Packaging.

- By Material: Foam Plastics; Paper & Paperboard; Plastics; Others.

- By Function: Cushioning; Blocking & Bracing; Void Fill; Insulation; Wrapping.

- By Application: Food & Beverage; Industrial Goods; Healthcare; Automotive; Household Appliances; Others.

- By Region: North America; Europe; Asia Pacific; Latin America; Middle East & Africa.

Frequently Asked Questions

Q1: What is the value of the protective packaging market as of 2024?

- A: USD 30.34 Billion.

Q2: What is the forecasted market size by 2035 and CAGR (2025-2035)?

- A: The market is expected to reach USD 49.60 Billion by 2035, growing at a CAGR of 4.58%.

Q3: Which region is the largest and fastest-growing?

- A: Asia Pacific is both the largest and the fastest-growing region.

Q4: Which segments dominate by type and material?

- A: By type, flexible protective packaging holds the largest share; by material, foam plastics lead.

Q5: What notable recent innovations have been introduced in the market?

- A: Examples include Storopack’s RENATURE® 3D panels made from plant starch (home compostable) and Sealed Air’s CRYOVAC® compostable overwrap tray with ~54% biobased content—the moves show strong momentum toward sustainable protective packaging alternatives.