Topsoe Selected for Landmark Green Ammonia Project in Saudi Arabia

Topsoe has been chosen as the ammonia technology licensor for ACWA Power’s Yanbu Green Hydrogen Project in Saudi Arabia, supporting the Kingdom’s energy transition.

Topsoe has been selected to license its dynamic ammonia technology for ACWA Power’s Yanbu Green Hydrogen Project in Saudi Arabia, supporting large-scale green ammonia production with engineering, proprietary equipment, and catalysts.

Topsoe, a global leader in advanced technologies for the energy transition, has been selected as the ammonia technology licensor for ACWA Power’s Yanbu Green Hydrogen Project in the Kingdom of Saudi Arabia. This selection marks a significant milestone for the project and reinforces Topsoe’s growing role in enabling large-scale green fuel production worldwide.

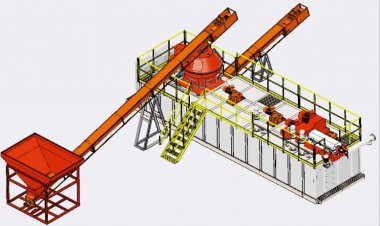

Under the agreement, Topsoe will supply its advanced dynamic ammonia technology. This solution allows green hydrogen produced at the Yanbu facility to be efficiently converted into green ammonia. In addition to licensing the technology, Topsoe will deliver engineering expertise, proprietary equipment, and specialized catalysts. These components will be provided to Sinopec and Técnicas Reunidas, the two companies jointly awarded the project’s Front-End Engineering Design (FEED) contract.

The collaboration further strengthens the long-standing strategic partnership between Topsoe and ACWA Power. By integrating Topsoe’s dynamic ammonia technology, the Yanbu project is expected to support industrial-scale production of green ammonia, contributing meaningfully to global decarbonization efforts and the development of sustainable energy systems.

Commenting on the announcement, Yassir Ghiyati, Chief Commercial Officer at Topsoe, highlighted the importance of green ammonia in the global energy transition. He noted that green ammonia is a vital solution for reducing emissions across energy-intensive industries and long-distance transportation. Ghiyati emphasized that scaling up proven decarbonization technologies is essential to achieving climate goals, and projects such as ACWA’s Yanbu development represent a major step in that direction.

From ACWA’s perspective, the partnership aligns closely with Saudi Arabia’s ambition to become a global hub for green hydrogen and its derivatives. Driss Berraho, Executive Vice President of Business Development for Green Hydrogen at ACWA Power, explained that the company is focused on developing full-scale, utility-level green hydrogen facilities. Through its collaboration with Topsoe, ACWA aims to convert competitively priced renewable energy into green hydrogen-based fuels, including green ammonia, at an industrial scale. He added that the project will help strengthen emerging hydrogen corridors linking renewable-rich regions with global demand centers while supporting the Kingdom’s Vision 2030 industrial transformation objectives.

The Yanbu Green Ammonia Project is designed as a gigawatt-scale green hydrogen development. With Topsoe’s technology, the hydrogen generated will be converted into ammonia, making it easier to transport and store using existing infrastructure. The initial licensing agreement covers the first mega-scale green ammonia units at Yanbu, each with a production capacity of approximately 2,700 metric tons per day. There is also an intention to replicate the design across additional units in future phases to further expand capacity.

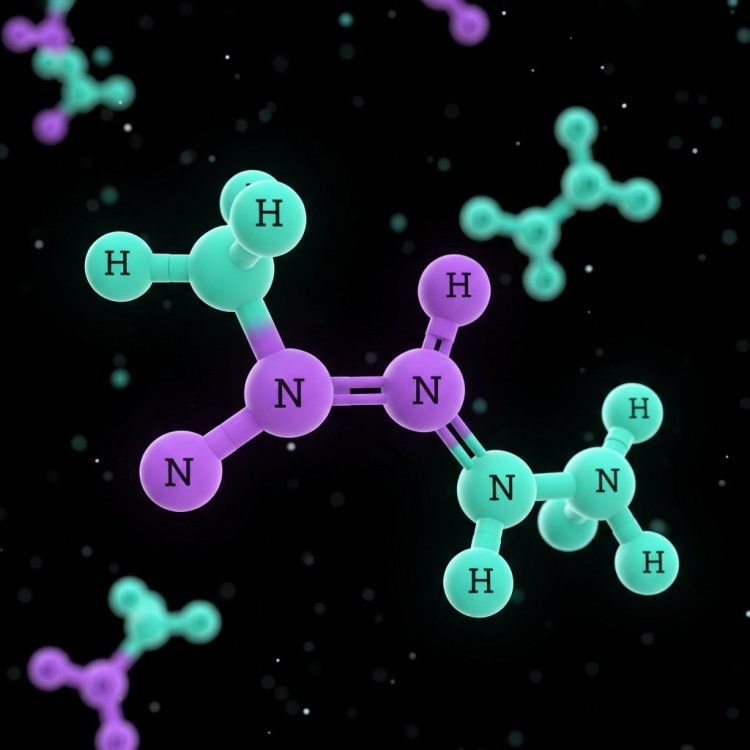

Green ammonia is increasingly recognized as a critical enabler on the path toward net-zero emissions. Beyond its role as a hydrogen carrier and low-carbon fuel, it offers significant potential for decarbonizing hard-to-abate sectors such as steel and cement manufacturing.

A key differentiator of Topsoe’s solution is its dynamic ammonia technology, which allows production levels to respond flexibly to fluctuations in renewable electricity supply. The process enables ammonia output to ramp up or down by at least 3% per minute, matching changes in hydrogen availability. This flexibility reduces the need for large hydrogen storage systems, leading to lower capital and operational costs while effectively storing renewable energy in a zero-carbon chemical form.